Ignition Coils

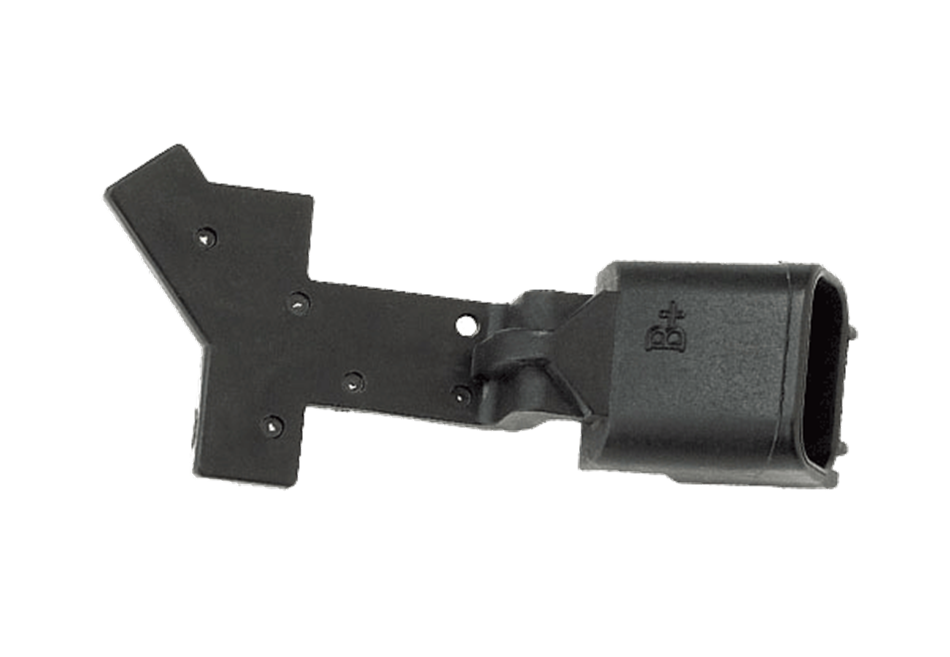

Ignition Coil-on-Plug (COP)

The ignition coil converts a low voltage current to high voltage energy that is delivered to the spark plug to ignite the air/fuel mixture within the cylinder. A coil-on-plug is designed to perform the functions of both the ignition coil which creates the spark energy, and the spark plug wire set that is designed to contain and deliver the high voltage energy to the spark plug. Intermotor® Coil-on-Plug assemblies are engineered and tested to meet or exceed OE standards for spark energy, impedance, and durability.

Designed to take the heat

Manufactured in Intermotor’s TS16949 certified, Bialystok, Poland facility, our specially formulated epoxy is high temperature shock-resistant to handle rapid changes in engine temperature and prevent cracking or coil damage. Engineered to bond with the coil housing and bobbins, our unique process eliminates air pockets and prevents moisture intrusion and thermal breakdown. It’s just one more design detail that makes us the import leader by design.

-

Tin-plated brass terminals for corrosion protection and improved electrical contact

-

Samarium-cobalt magnet in the core creates a strong magnetic field for maximum high voltage output at all speeds

-

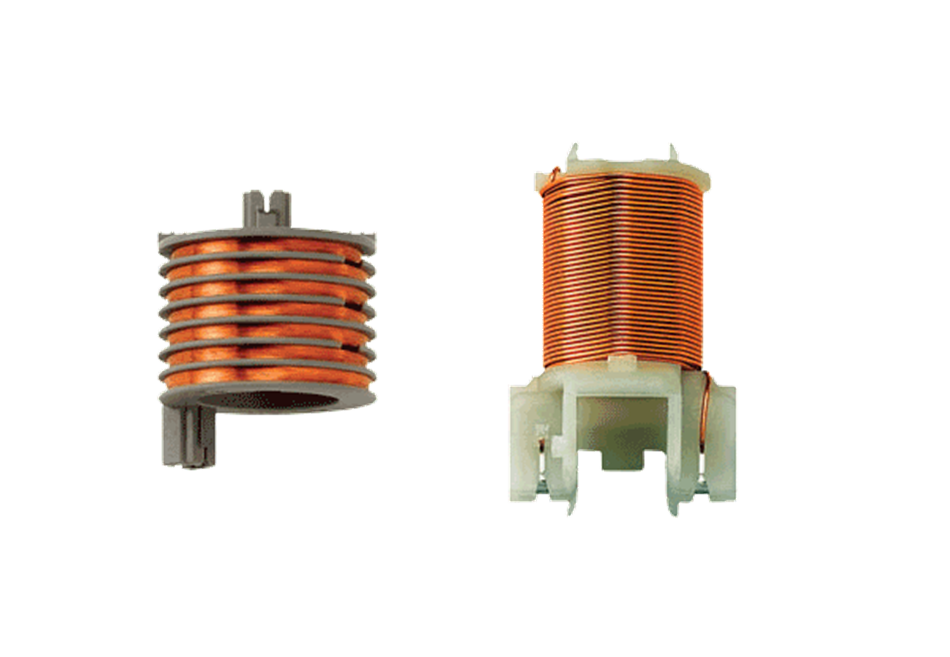

Primary coil winding made of 200°C/392°F insulated premium 25-gauge copper wire - engineered and precision wound to generate a strong magnetic field for improved performance

-

Improved secondary windings using ETP copper wire provides maximum voltage conductivity

-

Reinforced bobbins and additional winding bays prevent internal arcing, high voltage breakdown, and voltage flashover

-

Exact-match electronic module feedback signal

-

Bobbin is made from polyphenylene oxide glass material to prevent voltage leaking between the primary and secondary coils

-

Secondary coil windings are precision wound and trimmed to produce desired output voltage

-

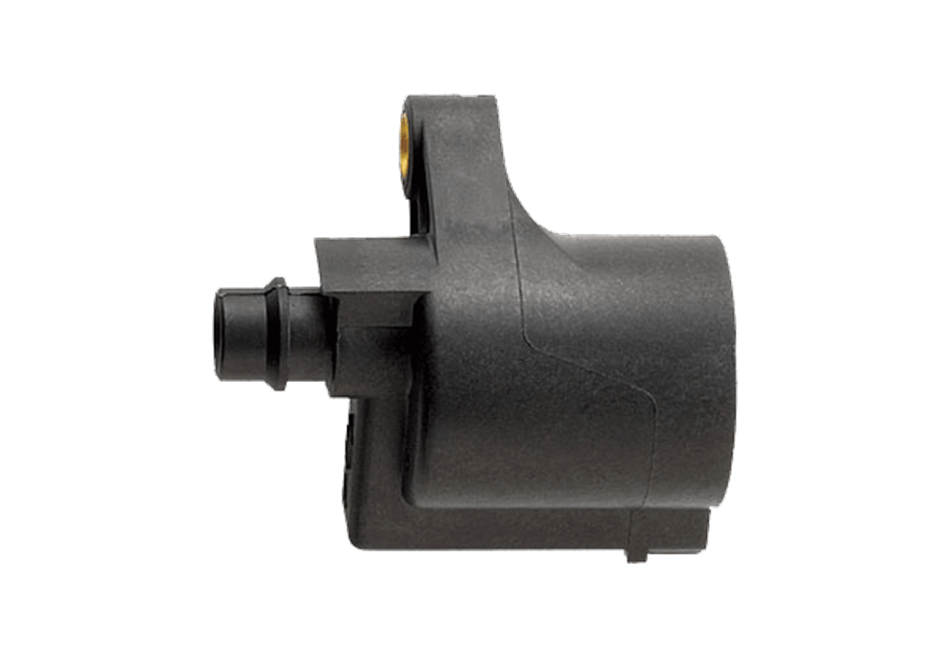

Housing constructed from high dielectric and impact resistant material that ensures long life in operating conditions

-

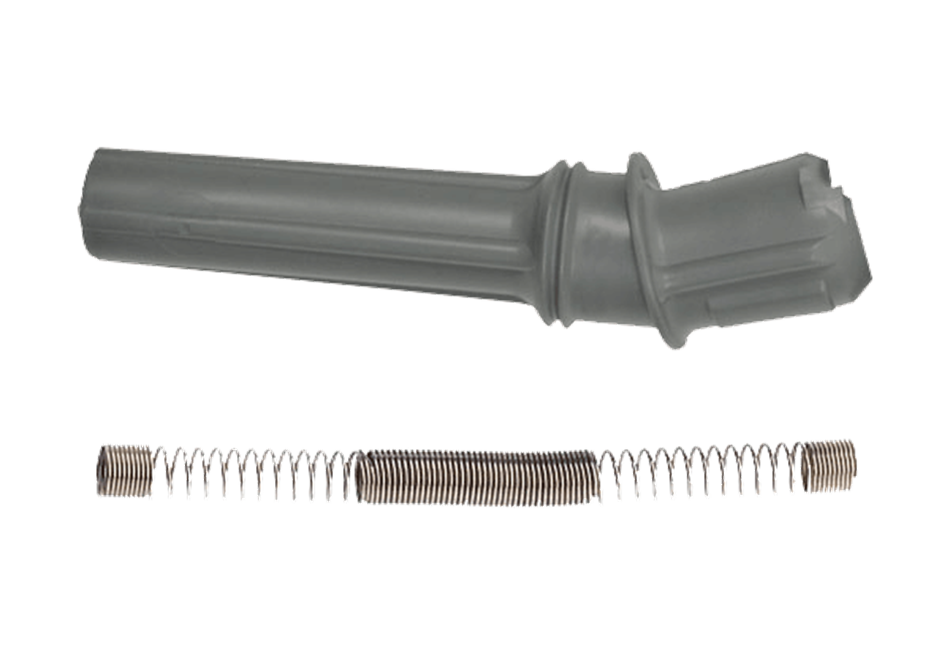

Stainless Steel Spring to resist corrosion

-

High-temp silicone boot stays flexible for easy removal during related component servicing

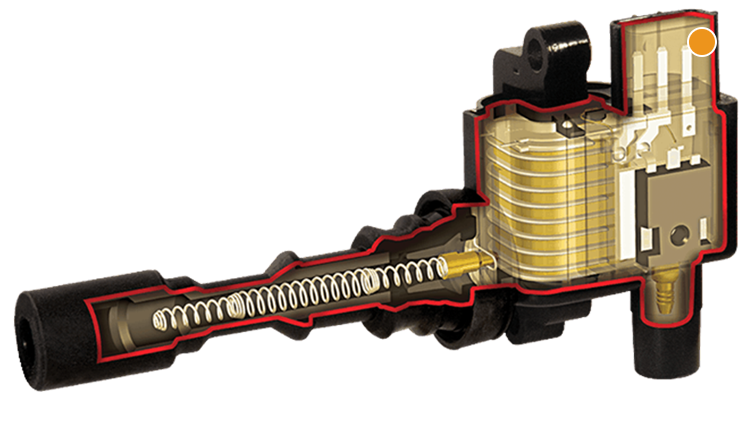

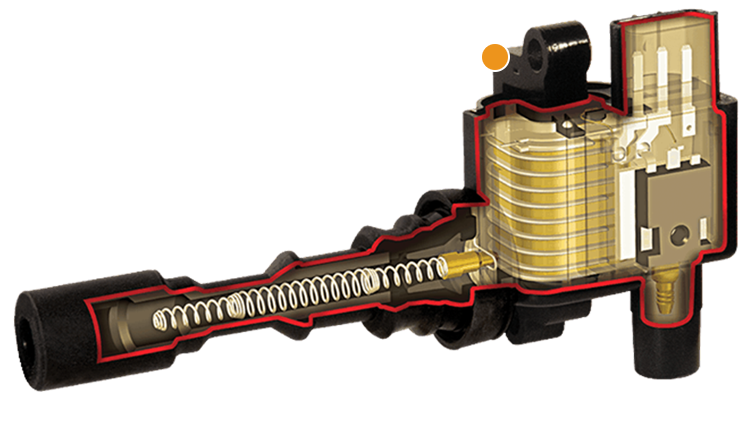

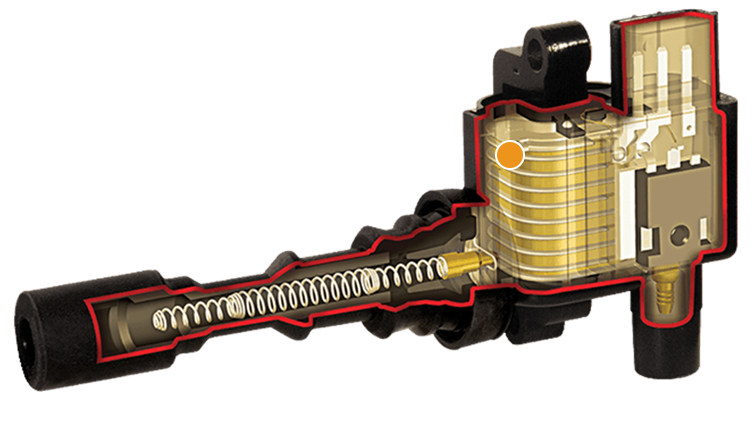

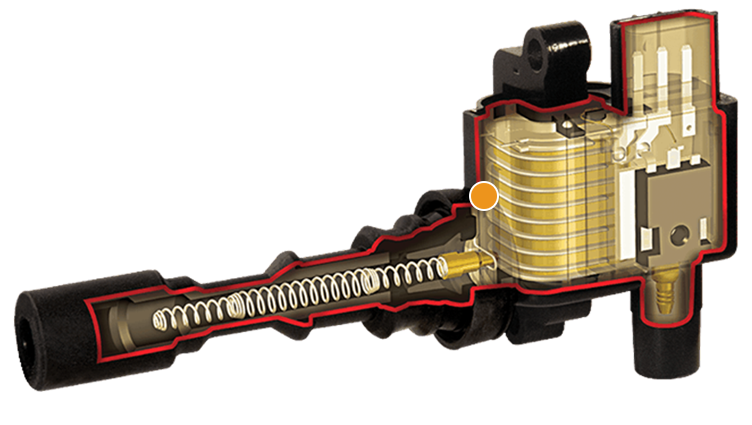

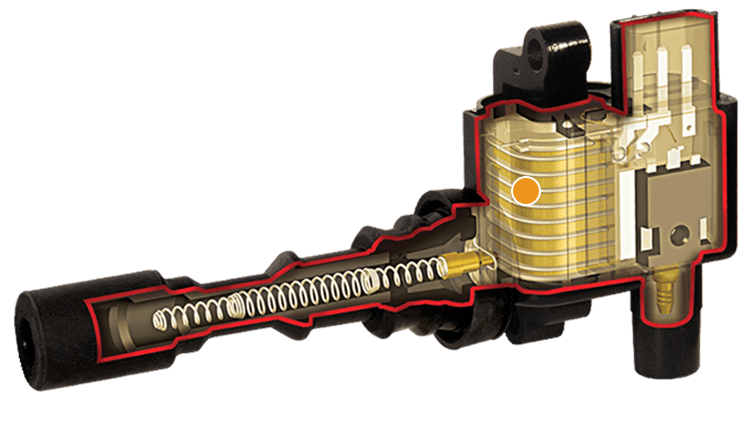

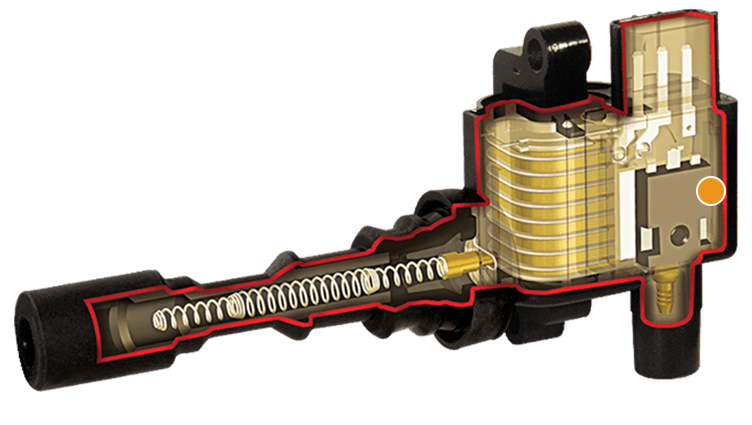

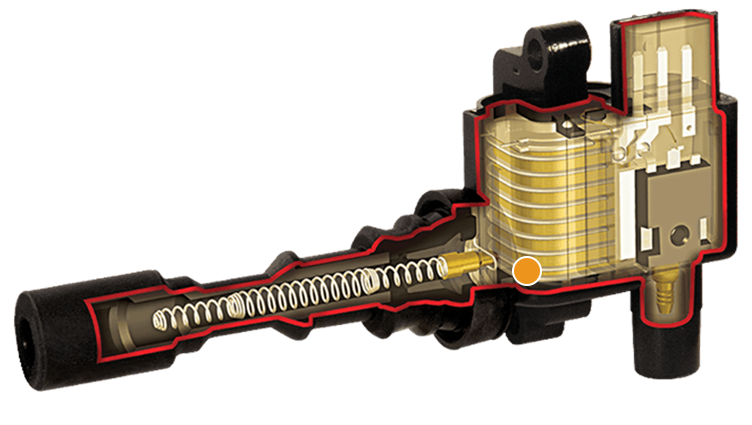

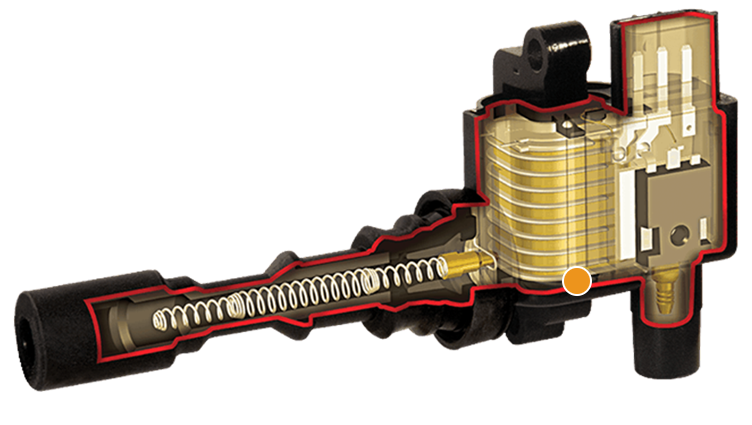

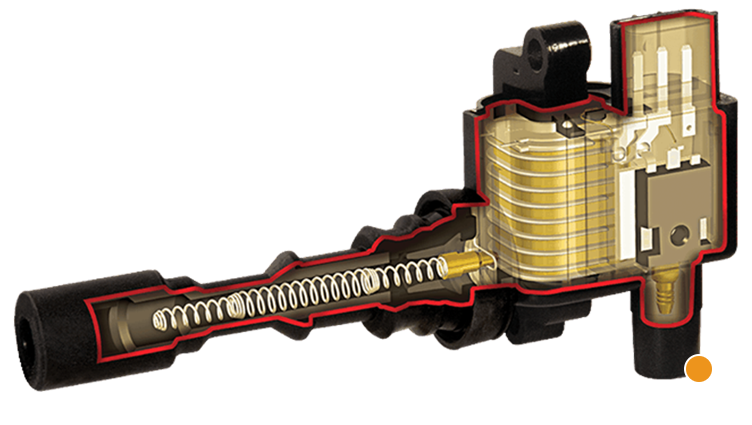

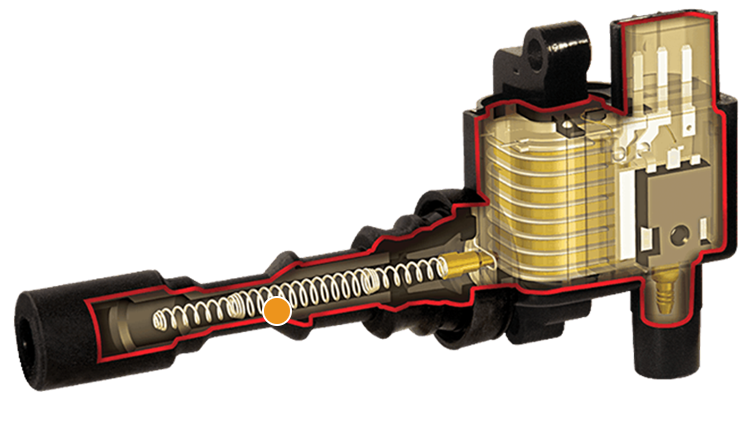

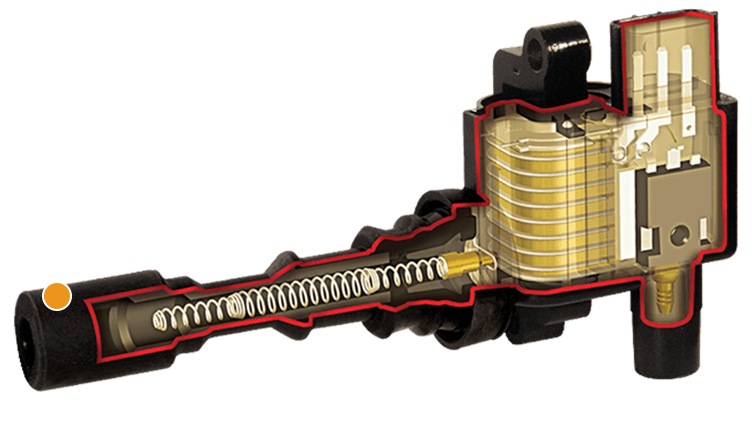

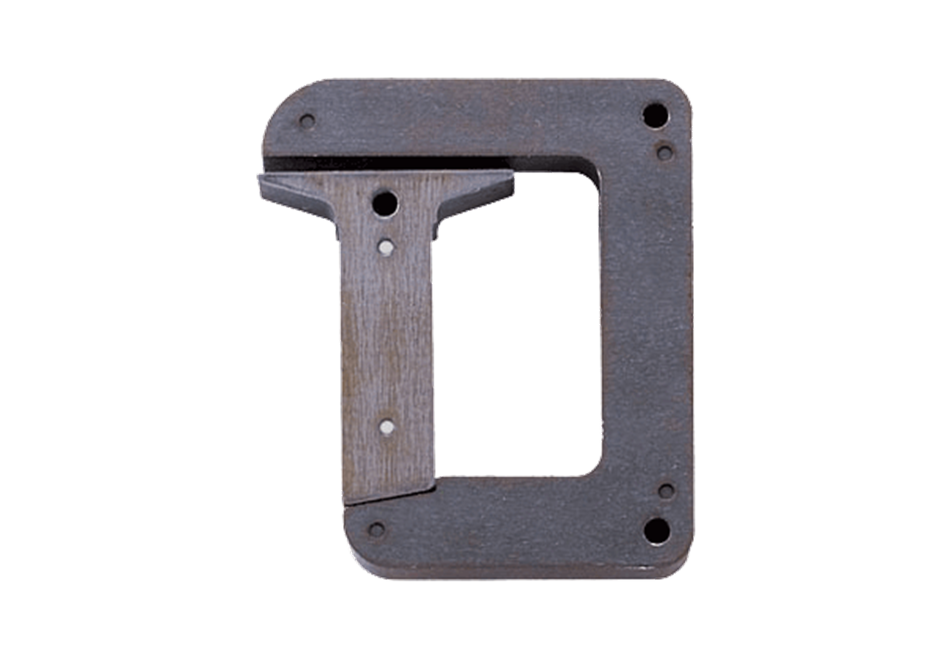

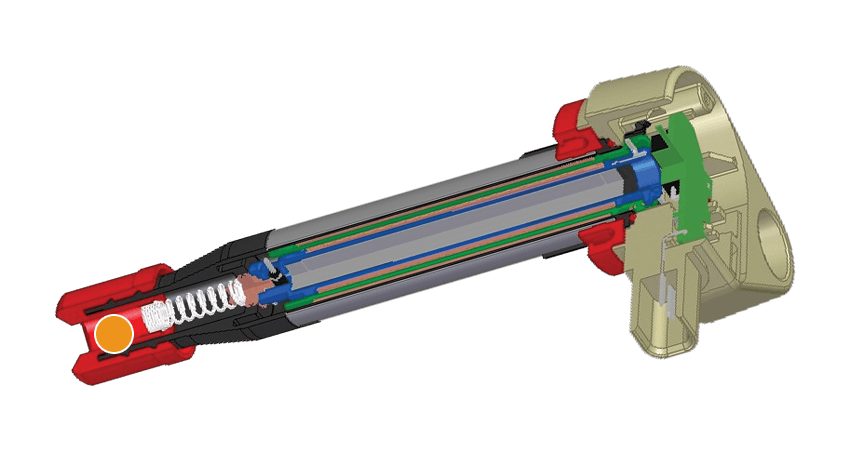

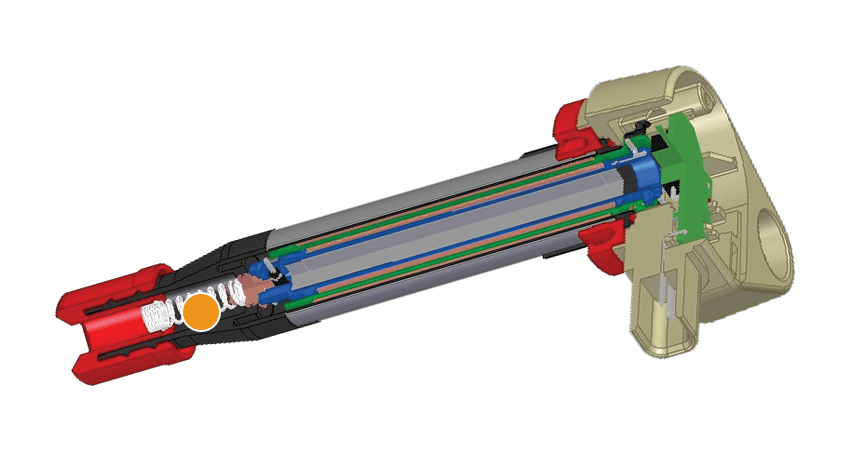

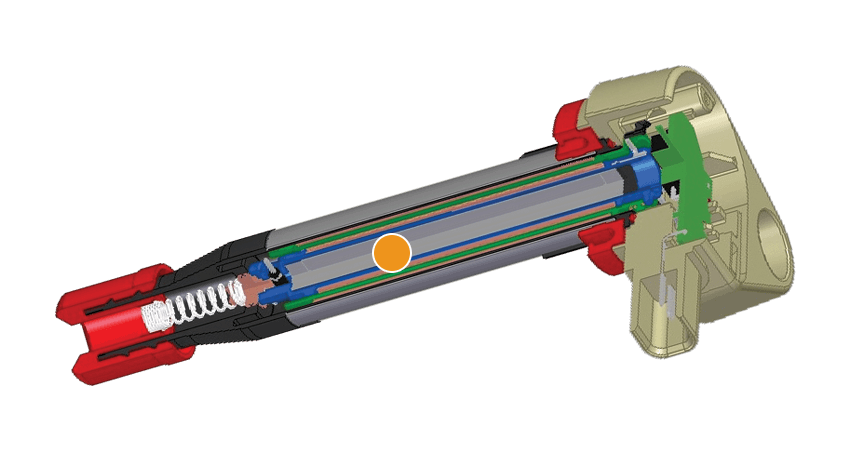

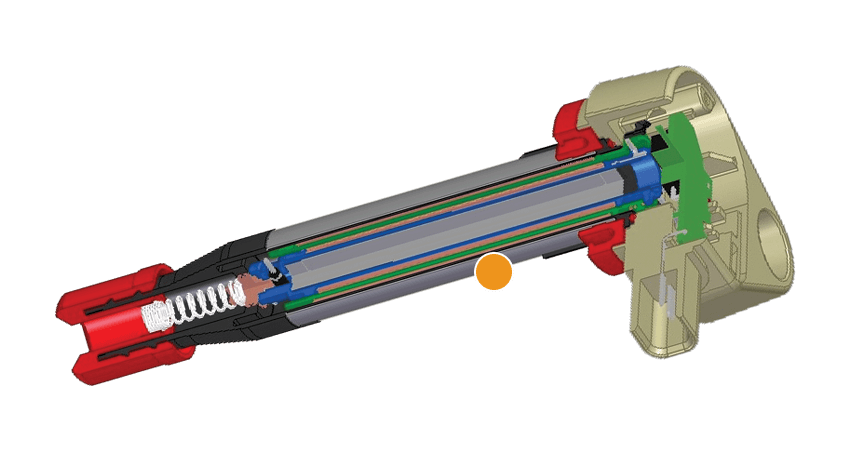

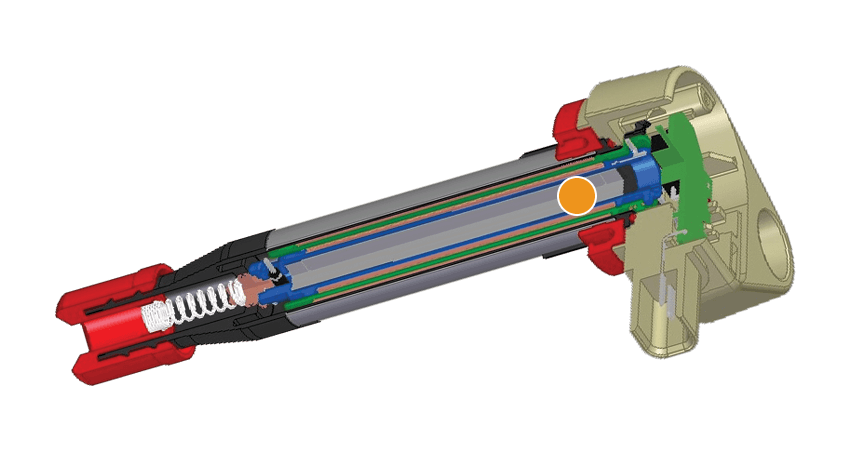

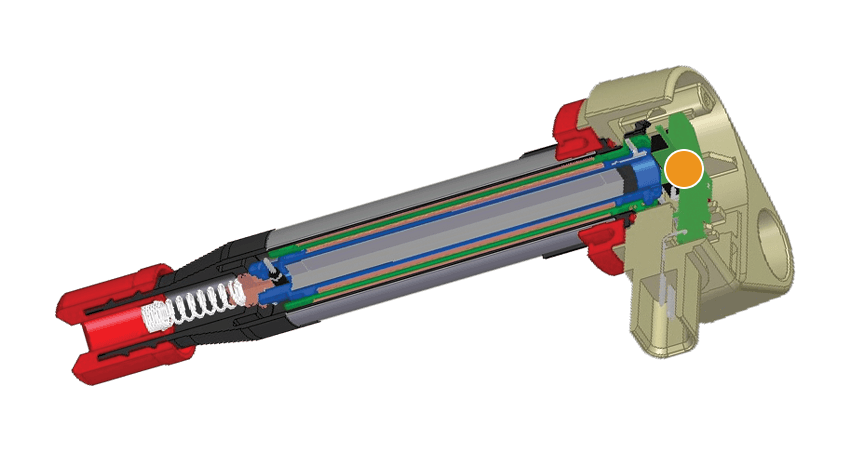

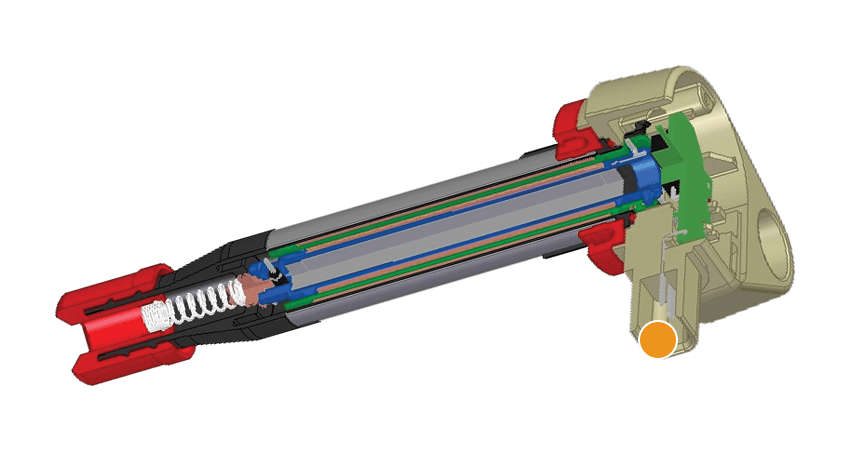

Coil-on-Plug Breakdown

A coil-on-plug is designed to perform the functions of the ignition coil (creating the spark energy) and the spark plug wire set (containing and delivering the high voltage energy to the spark plug). To ensure proper function, Standard® and Intermotor® Coil-on-Plug Assemblies feature premium-quality components.

Designed using advanced thermoplastics to ensure proper connection and resist fractures caused by heat and thermal cycling

High-temp boot prevents highvoltage leaks, while stainless steel spring with internal ferrite noise suppressor prevents radio frequency interference (RFI)

High-impact material bonds extremely well to epoxy to ensure longer life in all operating conditions

Internal neodymium permanent magnet surrounded by grainoriented magnetic-laminated steel maximizes high-voltage output at all speeds

Primary (25 gauge) and Secondary (43 gauge) copper wire ensure high-voltage availability for peak performance while reinforced bobbins prevent voltage flashover for extended service life

Manufactured using high-voltage resistant thermoplastics to prevent premature coil failure

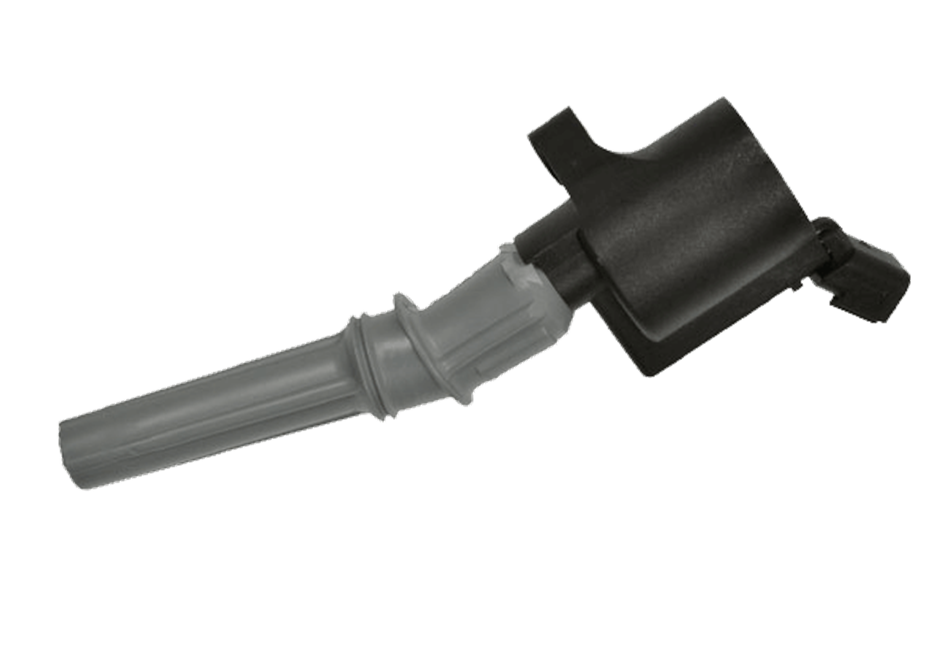

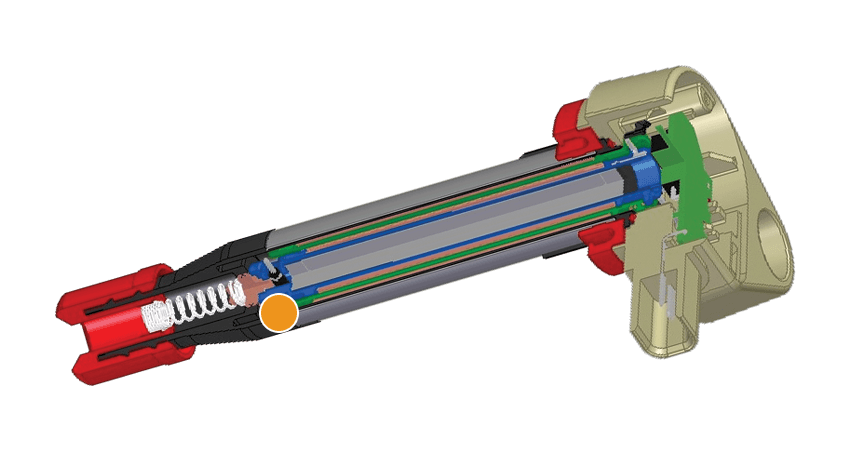

Pencil Coils

As engine technology evolves, coil-on-plug technology will continue to play an increasingly important part of ignition systems. One such technology is the pencil coil. Standard® and Intermotor® are leading the way with quality parts and exceptional coverage for this growing category. Take our UF242 Ignition Coil for example:

Tech Tip: If there’s been a failure such as a short, we recommend replacing the spark plug while you’re replacing the pencil coil.

-

Silicone rubber boot withstands extreme heat and provides superior insulation

-

Stainless steel spring resists corrosion

-

Primary and secondary bobbins made from fiberglass-reinforced polyethylene terephthalate prevent voltage flashover for extended service life

-

Internal core made from grainoriented electrical steel limits loss factor within magnetic circuit to reduce heat that may affect coil endurance

-

External core made from oriented silicon steel for durability

-

Neodymium magnet produces max high voltage output at all speeds

-

Electronic ignition module profile and feedback signal matches fit, form, and function of original

-

Tin-plated brass terminals improve electrical contact and protect against corrosion